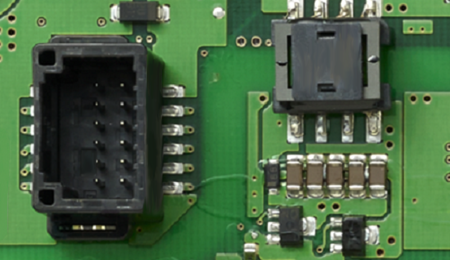

Polyplastics Co., Ltd., a leading global supplier of engineering thermoplastics, is successfully utilizing computer-aided engineering (CAE) analysis to forecast parts deformation during the reflow process when manufacturing connector parts made of liquid crystal polymer (LCP). These LCP connectors are finding growing use in mobile devices such as smartphones and switches, along with automotive-related applications.

LCP parts can expand considerably in the high-temperature conditions of the reflow process which can have an adverse effect on the flatness of a final product. Since heat deformation can cause poor bonding as a result of insufficient soldering to the metal terminals, it is important to find ways to reduce heat deformation, particularly as the market sees growing demand for smaller connectors. In response, Polyplastics looked to CAE and began considering design-stage deformation forecasting for molded articles in the reflow process.

LCPs like Polyplastics’ LAPEROS (R) resin is characterized by rigid molecular structures that are hard to bend and possess very little of the molecular interlocking behavior that is typical of most polymers. As a result, they deliver excellent dimensional accuracy and heat resistance and handle high reflow temperatures in the solder bonding process.

Polyplastics has identified three stages of deformation that can be forecasted by CAE analysis. These include post-molding initial deformation (warpage), at-peak heat deformation mainly due to the effects of thermal expansion plus post-molding shrinkage, and post-cooling deformation mainly attributed to the effects of thermal shrinkage.

Polyplastics will continue to work on the development of CAE analysis technology to improve its accuracy and expand its range of applicability.

For more information, visit https://www.polyplastics.com/

LAPEROS (R) is a registered trademark of Polyplastics Co., Ltd. in Japan and other countries.

About Polyplastics

Polyplastics Co., Ltd. is a global leader in the development and production of engineering thermoplastic solutions. The company’s broad product portfolio includes POM, polybutylene terephthalate (PBT), polyphenylene sulfide (PPS), and liquid crystal polymer (LCP). The company has the largest global market share of POM. With more than 50 years of experience, the company is backed by a strong global network of R&D, production, and sales resources capable of creating advanced solutions for an ever-changing global marketplace.

SOURCE: Polyplastics Co., Ltd.